Vita Wall

TAs: Hadi El Kebbi, Sophia O’Neil, Matt White (ARCH802)

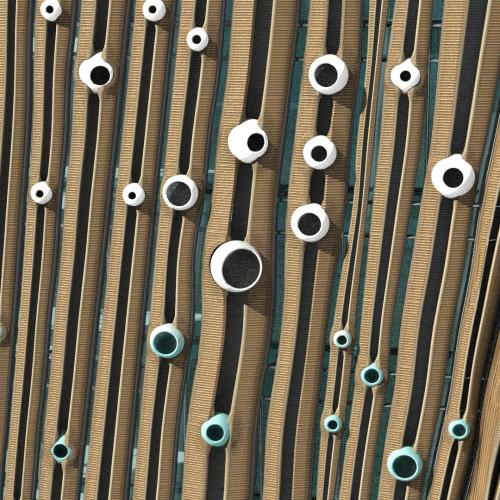

Vita Wall involved the development of a novel robotic ceramic production process and its implementation in a ceramic architectural façade screen proposal. In the field of architectural ceramics, robotic fabrication methods have broadened the variety of manufacturing techniques used since ancient times. Despite advancements in ceramic additive manufacturing and slip-casting, there are limited instances of combining these two distinct fabrication methods. This research explores how different clay shrinkage ratios between bone-dry spherical slip-cast elements and additively manufactured parts can be leveraged to manufacture freely rotatable embedded elements within ceramic facade components, enabling post-manufacture reconfigurability. An adaptive manufacturing approach was developed that periodically embedded slip-cast elements into an additively manufactured part during its manufacture. The method utilises computer vision to inform robotic grasping and placement of slip-cast elements without damage to the wet slip-cast part or recently deposited additively manufactured layers. The method demonstrates the potential for the manufacturing approach to be automated to support higher-volume production runs. By combining slip-cast and additive manufacturing methods in a ceramic façade screen, additional functional embedded features become possible, where rotatable hollow slip-cast components could be integrated into a kinetic or repositionable facade system. Such approaches can support the periodic re-alignment of parts in relation to environmental or species habitat requirements. The research was applied to a speculative façade screen design that can be reconfigured to support finer-scale adaption to the specifics of a building’s urban microclimate than site surveys or environmental modelling can ascertain in advance. A series of rotatable hollow embedded parts are envisaged to provide habitat to various small species as a controlled form of urban re-wilding. This speculative design is also demonstrated in a multi-part façade screen prototype fabricated using the research methods.