"These Things Swirl”

TAs: David Forero (ARCH802)

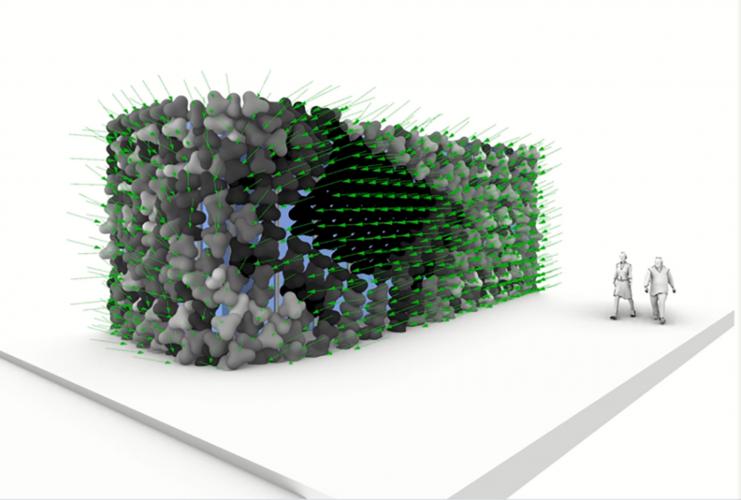

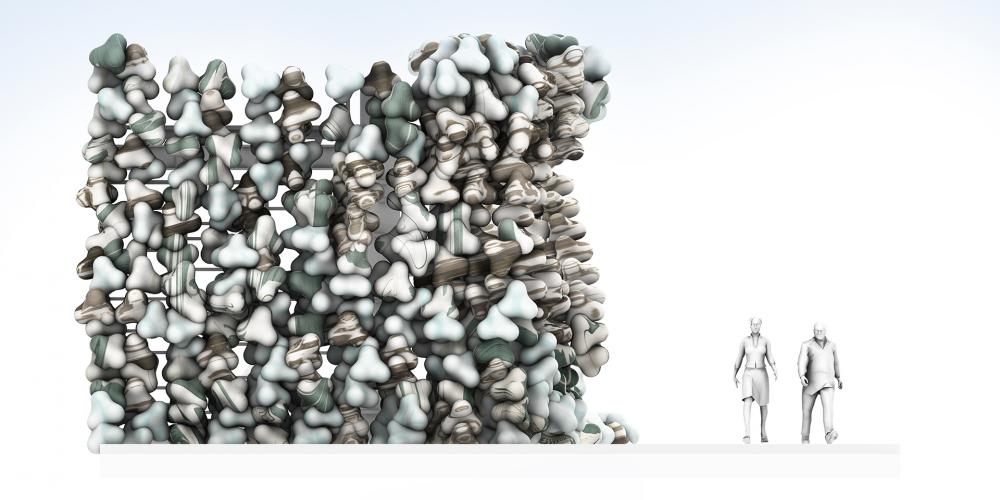

Slip casting is a staple process in the creation of complex geometries in ceramics, and widely used for the manufacturing of sanitaryware and fine porcelain. The phase-changing nature of the slip casting makes the process ideal for the production of complex, standalone components; however, it currently lacks the ability to produce meaningful visual variation between components without the use of an entirely new mold. This research explores a novel technique for creating bespoke, slip cast artifacts through the use of 6- axis robotic motion to appropriate methods used in plastic rotational molding to slip casting. By incrementally injecting different ratios of colored slip into the mold while it is rotated, we are able to achieve variable color, pattern, and structure. Because of the highly precise nature of the robotic motion, this variation can be repeated with a relatively high degree of accuracy. In addition, incremental injection of slip allows a full cast to be achieved with a minimal amount of slip, entirely removing the draining process used in traditional slip casting. A prototypical façade part was developed that leverages the developed slip casting method to produce diverse marbling within a series of tetrahedral components. Before each component is bone-dry, and still malleable, they are assembled using a custom robot pick and place routine that attempts to subtly squish some of components against each other. The orientation and placement of each element was determined within a custom-developed generative design and material physics simulation method. The research aims to introduce new variables into the world of mass-manufactured slip-cast ceramics in the form of controllable color and pattern.