Robotic Approaches to Dynamic Slip Casting

TAs: Hadi El Kebbi, Sophia O’Neil, Matt White (ARCH802)

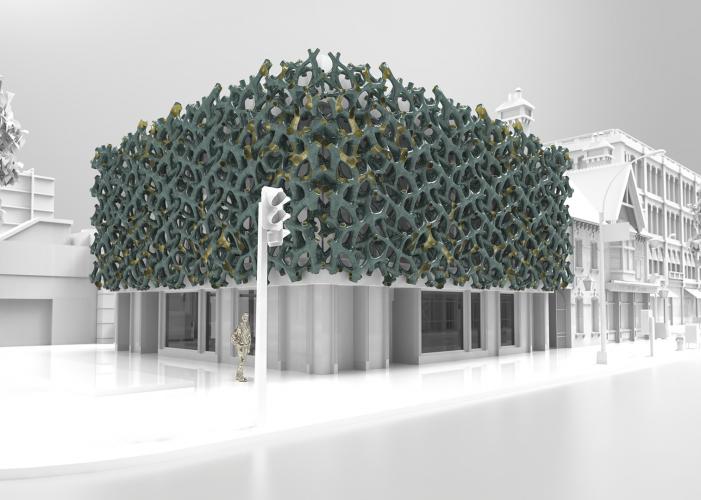

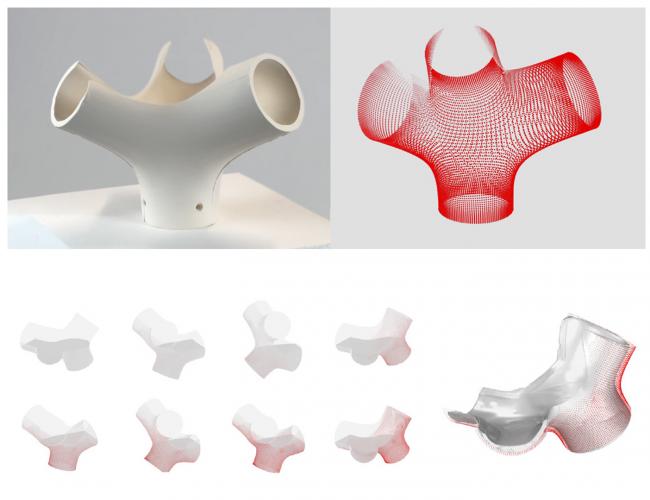

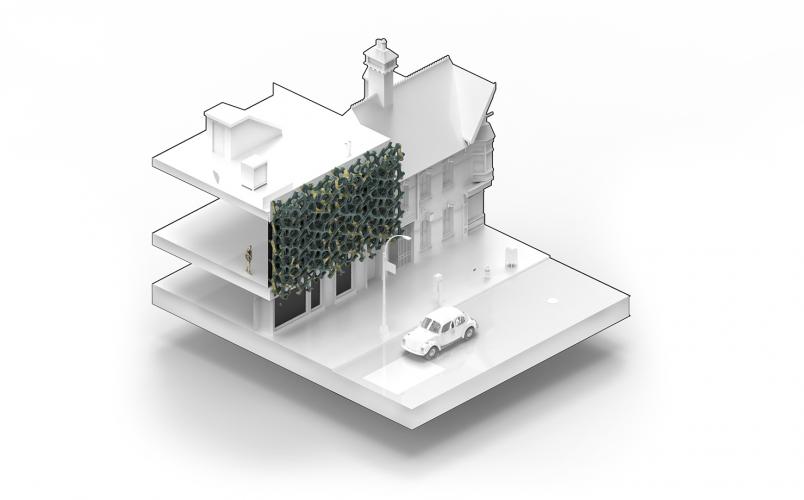

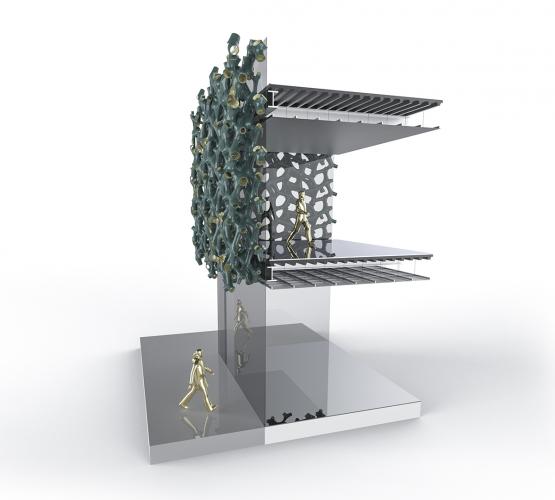

Slip-cast ceramics can produce unrivalled formal complexity and geometrical precision compared to other ceramic manufacturing approaches. While it is the preferred production approach to fine porcelain and sanitary ware products, its limitation in producing variable components without unique molds presents challenges for the method’s integration into architectural practices where variability is often advantageous. This research develops a method to support the production of geometrically varied slip-cast parts from a common mold, through the robotic rotation of the mold during the slip solidification process. Challenges arising from the method such as slip formation and edge quality, are addressed through the incremental injection of slip during manufacturing on a custom end-effector tool, and the development of simulation software to predict slip formation in real-time. The simulation software is also used to generate robot manufacturing instructions in relation to a design input and serves as a design visualisation tool. The capacity for the approach to produce geometric variation within an automated slip-casting process is demonstrated in a full-scale prototype façade screen assemblage comprised of 28 parts cast using four different molds, and an overall architectural façade screen design comprised of thousands of pieces that uses the same four variations of mold. Altogether, the research demonstrates an approach to the design and manufacture of geometrically varied slip-cast parts for architectural ceramic façade screens that integrates design and manufacturing activities whilst reducing waste and cost associated with the production of unique one-off use molds.