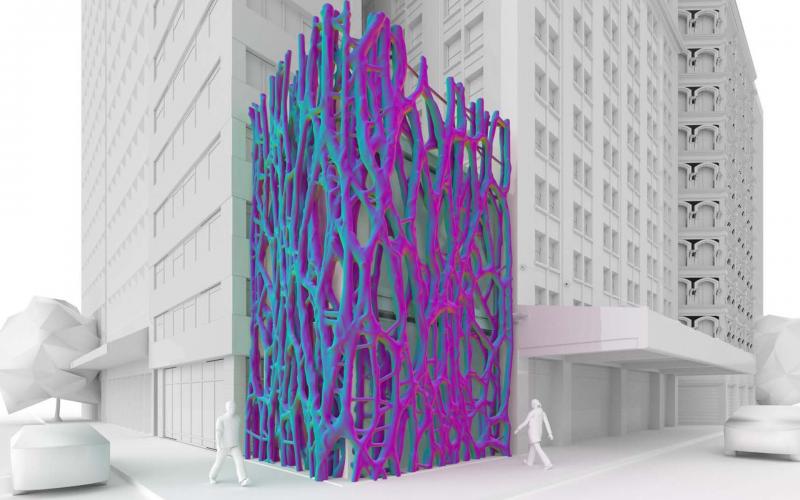

Non-Planar Deposition for Branching Ceramic Assemblies

Students: Cici Chenxiao Li, Zilong Han, June Mingyang Yuan

Instructors: Robert Stuart-Smith (ARCH802), Nathan King (ARCH806), Billie Faircloth (ARCH808), Jose-Luis García del Castillo y López & Jeffrey Anderson (ARCH804)

TAs: David Forero (ARCH802)

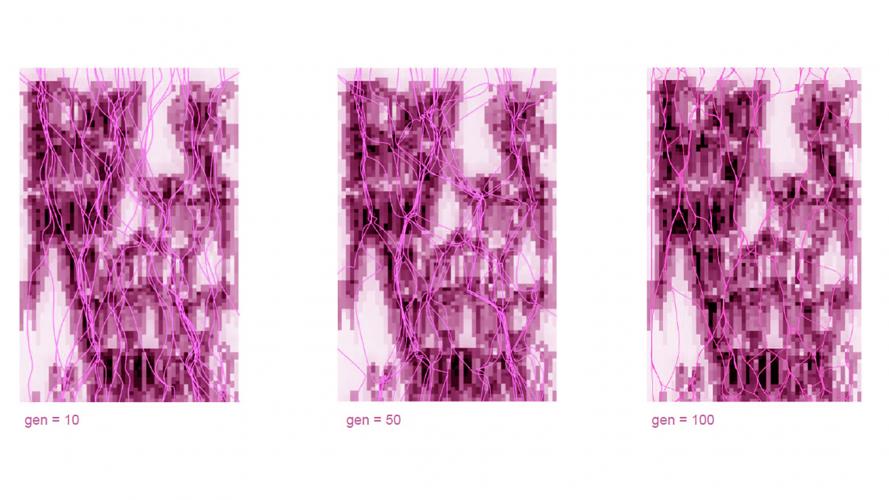

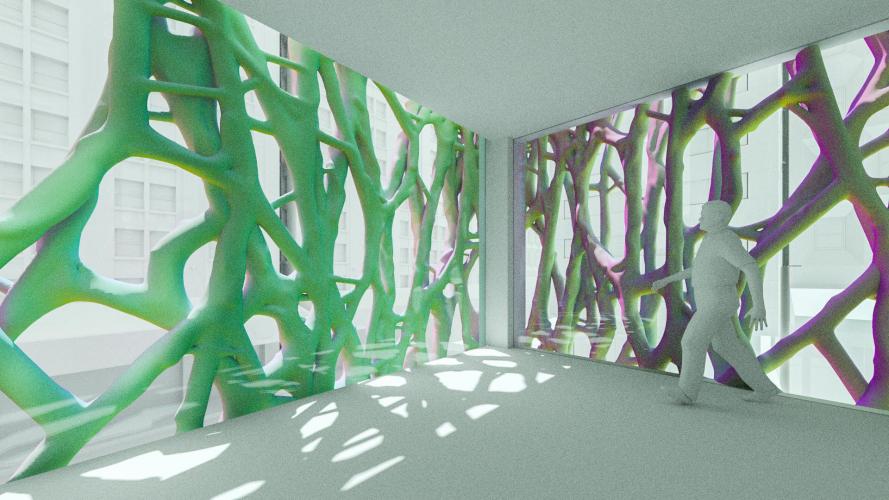

Clay extrusion 3D printing offers opportunities for innovation in the architectural ceramics industry which currently relies on manufacturing methods that are practically and economically constrained to large-volume production runs. However, due to clay's plasticity and semi-liquid properties, technical challenges remain in finding printable geometries, scaling components, and in developing methodologies for multi-robot cooperation. This research explores the customization potential of clay extrusion 3D printing by adopting a non-planar deposition method for branching structures composed of cylindrical components. It focuses on workflows for printing truncated and bifurcated branches, exploring the relationship between branching component equilibrium and non-planar deposition parameters. These experiments focus on fully controlling the non-planar deposition method while taking advantage of the automatic control granted by a 6-axis industrial robot. The research is demonstrated in a 1.3m high ceramic assemblage prototype and a multi-layered building façade design, where the robotic manufacturing method is leveraged to create a highly bespoke, variable façade through an approach that holds potential for such large-scale industrial applications.