Light-ING

Students: Jingjing Yan, Siyu Dong, Xiangguo Cui, Shunyi Yang

Instructors: Robert Stuart-Smith (ARCH802), Nathan King (ARCH806), Billie Faircloth (ARCH808), Jose-Luis García del Castillo y López & Jeffrey Anderson (ARCH804)

TAs: David Forero (ARCH802)

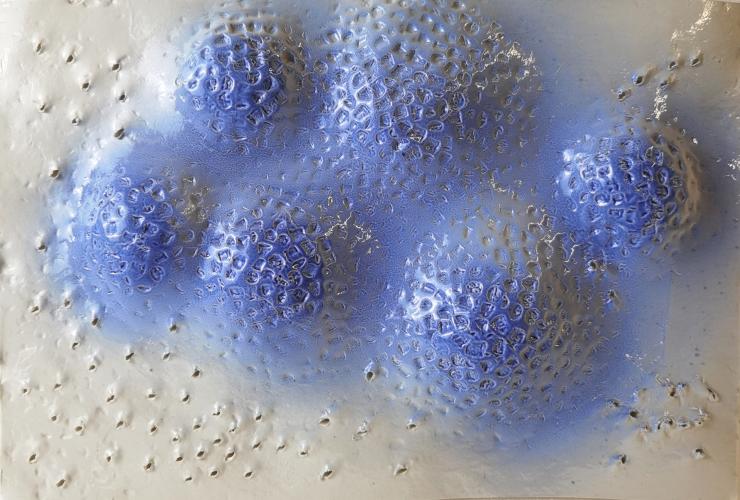

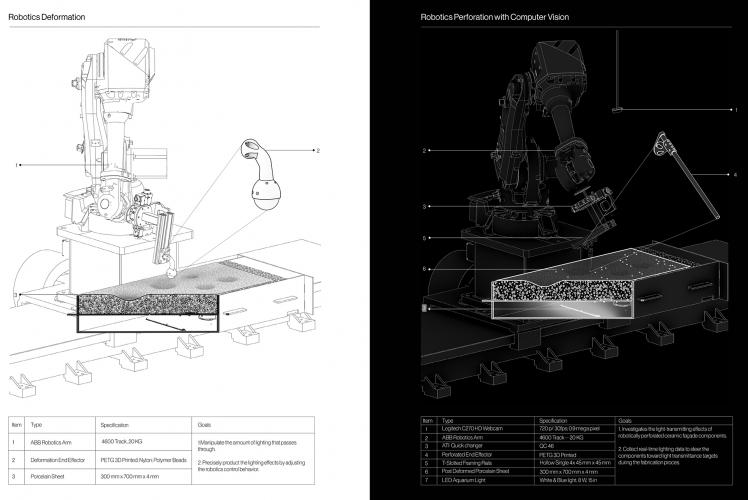

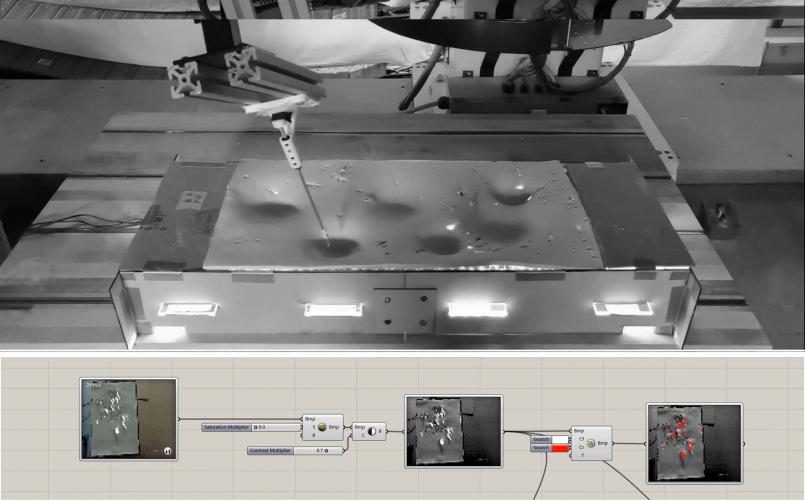

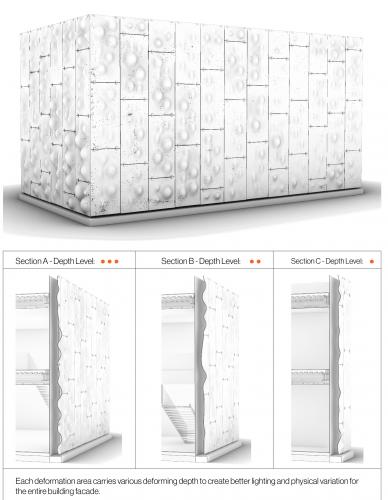

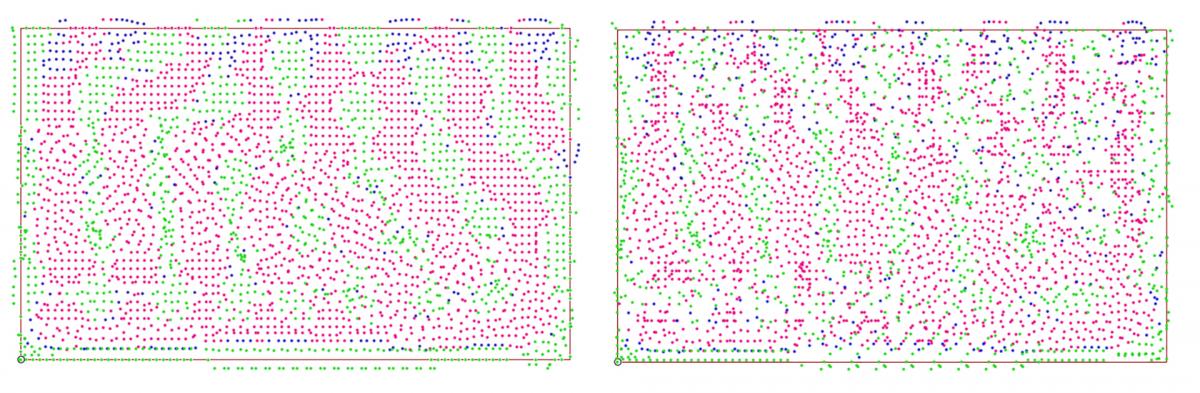

Building envelope design incorporates a range of light-related global analyses that often inform environmental performance, geometry, or material composition. Extending envelope light-related analyses to include lighting transmittance effects on a building’s interior presents opportunities to explore the translucency, porosity, and form of façades in novel ways, yet requires design approaches that are tailored to the production and evaluation of such visual effects. Although ceramics are widely used in façade construction, they offer a wide range of transmittance and deformation potentials that are relatively unexplored architecturally. This research investigates different clay bodies physio-material properties and their transmittance post-firing, together with their relationship to form, material properties, and porosity, and how these correspond to different interior and exterior lighting effects. Glazed architectural ceramic components are fabricated using a custom robotic manufacturing and tooling method that is able to form clay into variable panel configurations through an iterative manipulation method that does not require costly and materially wasteful molds. In addition to controllable variation in ceramic membrane thickness provided within the forming method, a real-time adaptive perforation control and tooling method allows components to incorporate a distributed field of variably orientated holes to achieve a specified lighting transmissiveness in relation to computer vision and sensor data in addition to 3D design criteria. A semi-autonomous process manufactures panels that are partially designed within a computational approach to 3D building performance analysis metrics and façade design, and partially during fabrication where a desired light transmittance level arises from the manipulation and perforation of each panel in relation to live sensor data feedback. The research approach exploits the malleability and translucency of porcelain ceramics within an industrially scalable bespoke process and is realised in a partial facade assemblage that demonstrates a variable panel geometry, light transmittance, and material aesthetic. The project recasts manufacturing as a creative enterprise where feedback enables the approach to operate as a variable, objective-driven form of real-time design agency.