HydroCeramic Facade Systems

Students: Christine Khouri Sader, Sophia O’Neill, Ryan Liao

Instructors: Robert Stuart-Smith (ARCH802), Nathan King (ARCH806), Billie Faircloth (ARCH808), Jose-Luis García del Castillo y López & Jeffrey Anderson (ARCH804)

TAs: David Forero (ARCH802)

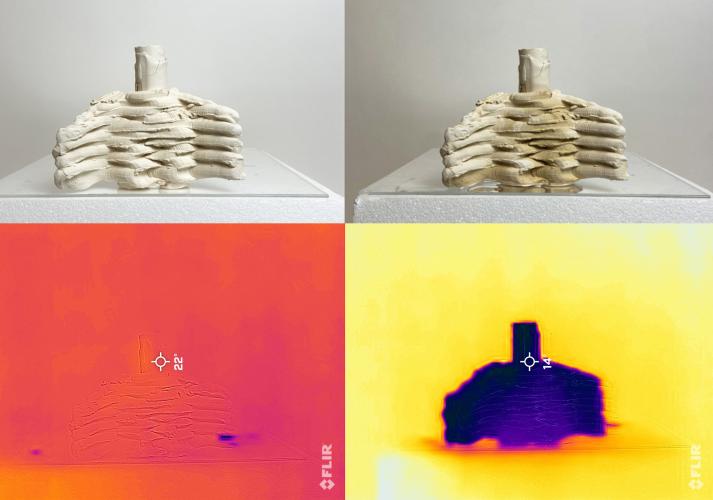

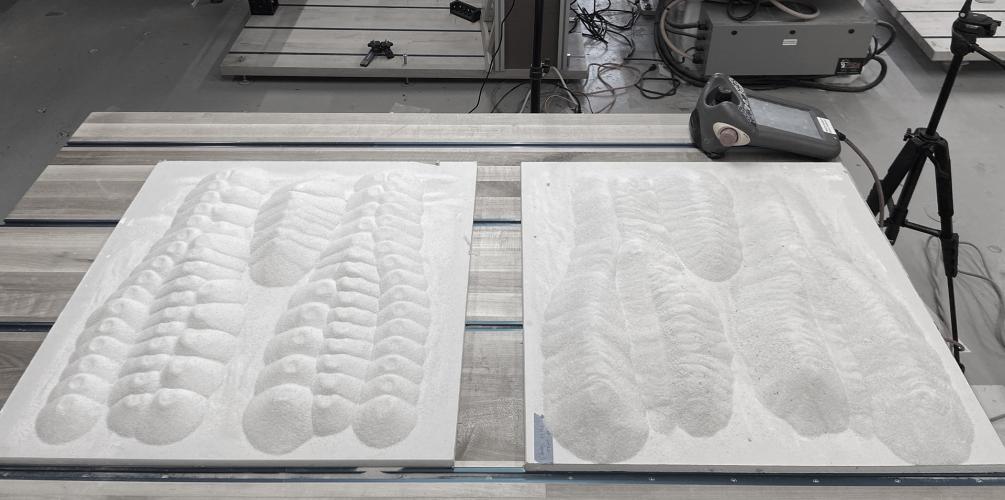

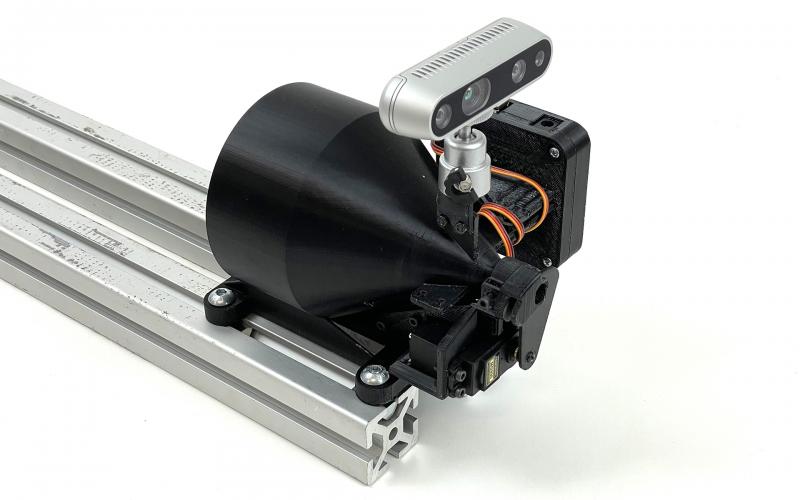

This research explores the embedding of slip-cast geometries inside of robotically deposited clay to create a hybrid manufacturing approach to produce a mono-material architectural ceramic façade prototype that utilises water seepage to enhance passive cooling. The method extends clay additive manufacturing capabilities by utilising a robotically deposited sand substrate as a temporary formwork scaffold to support the robotic deposition of clay, allowing shallow double-curved surfaces to be fabricated that would otherwise collapse without support, and alleviating the need for wasteful formwork methods as the sand involved is able to be reused. Clay slip-casts are embedded between two layers of robotically deposited clay. A robot control method and tooling was developed for the deposition of the sand mold, and for scanning and the adjustment of clay deposition trajectories to adhere to both sand surfaces and embedded slip-casts. Bisque fired prototypes were filled with room temperature water and tested for their cooling capacity as they seeped the water to their exterior surfaces. Results demonstrated that the seepage’s exposure to air produced a substantial cooling effect. A select number of slip-cast molds were designed to support a degree of variation when used in various assembled combinations. The robotically deposited clay extends this variation by supporting one-off diverse surface geometries around each slip cast. To explore a larger speculative prototypical façade design, a computational method was developed to control the distribution and orientation of the slip casts in relation to solar radiation exposure and prevailing winds. A water seeping façade design is proposed that arises from the custom-developed manufacturing method that was informed by, and hybridizes ancient pottery practices and robotic additive manufacturing.