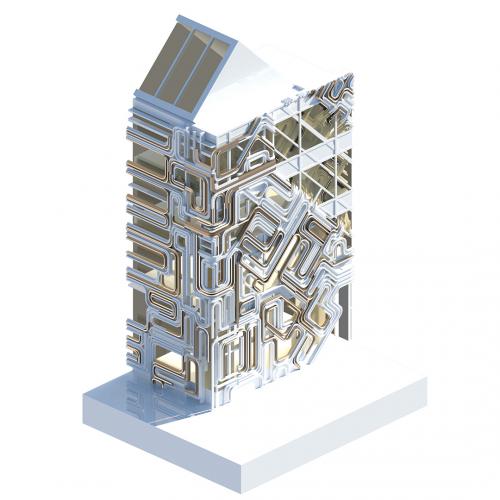

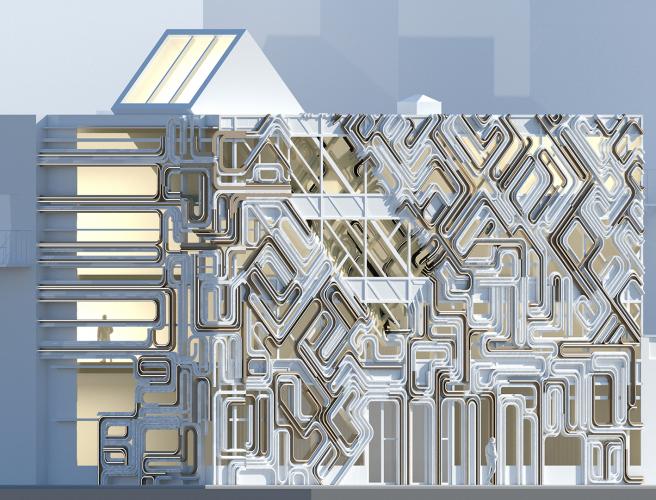

Filigree Façade

TAs: Hadi El Kebbi, Sophia O’Neil, Matt White (ARCH802)

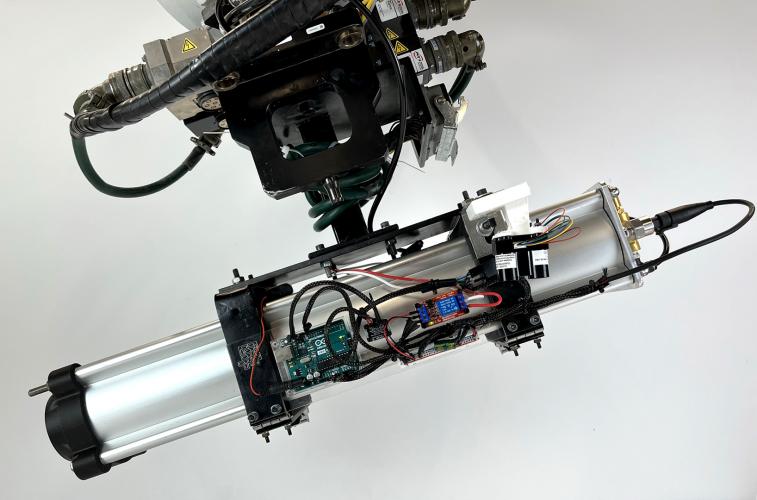

The Filigree Facade is a design research project that provides an integrated approach to the design and manufacturing of a ceramic architectural façade screen. The research hybridises industrial die-extrusion manufacturing with industrial robot additive manufacturing methods to produce geometrical variation in parts by leveraging dynamic kinematic possibilities in a robot production process. The research focuses particularly on the development of custom end-of-arm tooling capable of producing variable extrusions and an agent-based ceramic facade computational design method tailored to the production method’s constraints. The current state-of-the-art for robotically extruded architectural ceramics is primarily concerned with an iterative horizontal layering method used to produce a single architectural part. Although this additive manufacturing technique is often referred to synonymously as “extrusion,” it bears little resemblance to the industrial extrusion of architectural ceramics, which typically utilizes fixed, geometric die profiles extruding onto a linear material conveyor to rapidly produce whole architectural parts. The research focuses particularly on the development of custom robot end-of-arm tooling designed to accept interchangeable dies and accompanied by a sensor system that provides in-sights into the variables affecting extrusion. By mounting the extruder to the articulated robot arm, a vast number of extrusion tool paths were able to be achieved, enabling significant geometrical variation between parts. A design for a ceramic architectural façade screen registers this variation through the placement of parts in an orientation where each extrusion trajectory lies in the plane of the façade. An agent-based design methodology further highlights the variable porosity and directionality in the façade screen by enabling regions of inter-part alignment and divergence. A multi-part assembled prototype was designed and manufactured using the research methods and demonstrates the possibility of robotic extrusion being applied to architectural facades, where the attained variability could support design outcomes being more responsive to context while creating a complex aesthetic language.