Ceramic Forest

TAs: Hadi El Kebbi, Sophia O’Neil, Matt White (ARCH802)

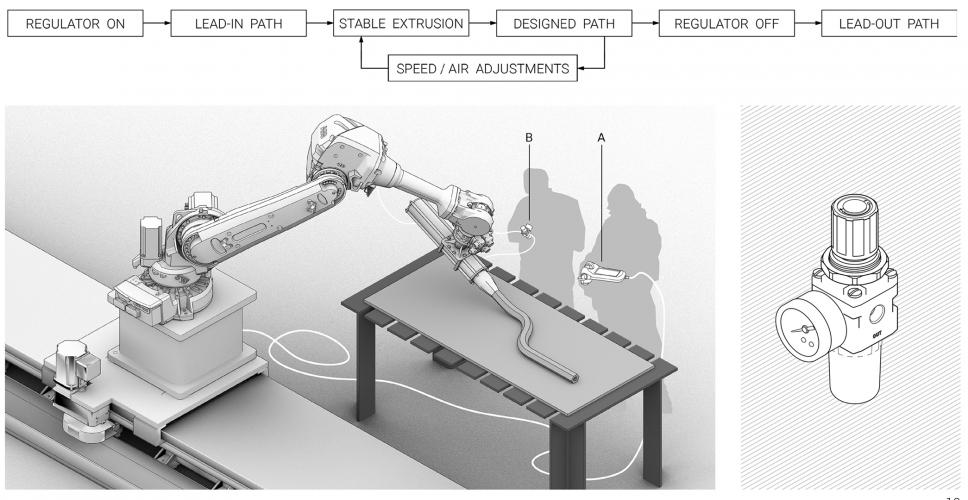

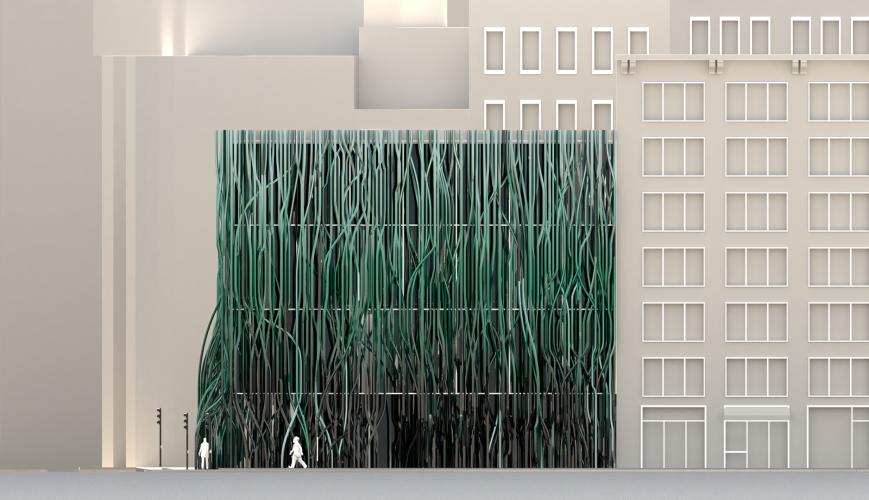

Extrusion is a well-established industrial production technique commonly used for making architectural ceramic clay parts in high-volume for façade cladding and other applications. In mass production, an auger pushes clay out of a reservoir through a die profile onto a conveyor belt. While the method enables elaborately profiled extrusions, the extrusion and die allow for no degree of variability across the production of several parts. Ceramic Forest explores how robotic fabrication and clay extrusion techniques can be integrated into a variable production process by mounting an extrusion system and die on an industrial robot end-of-arm tool. Experiments exploring fabrication parameters including the clay body water content, die geometry, air pressure, and a robot's motion trajectory informed the development of a hexagonal die-cast extrusion part that supports the ability for several parts to be bundled together to form a spatial façade screen system. The research is demonstrated in the production and bundled assembly of a full-scale partial façade screen prototype comprised of geometrically distinctive parts, and a larger architectural façade screen design proposal. A computational design method was also developed for the architectural façade that incorporates the research’s established fabrication constraints. Together, these developments illustrate an approach to variably formed die-formed ceramic extrusion and a computational design approach to the manufacturing method’s application in architectural façade screens.